WEARING PARTS

New production and the reconditioning of wearing parts are also part of our range of services.

In order to meet our high quality requirements, we produce exclusively in our own factory in Germany.

- 01 Goosenecks

- 02 Shot sleeves

- 03 Plungers

- 04 Plunger Rods

- 05 Plunger Rings

- 06 Energy Saving Nozzles

- 07 Nozzle Tips

- 08 Crucibles

- 10 HP Heating Cartridges

- 11 Thermocouples

- 12 Angular Thermocouples

- 13 Digital Temperature Controller

- 14 Twin-Circuit Temperature-Controller

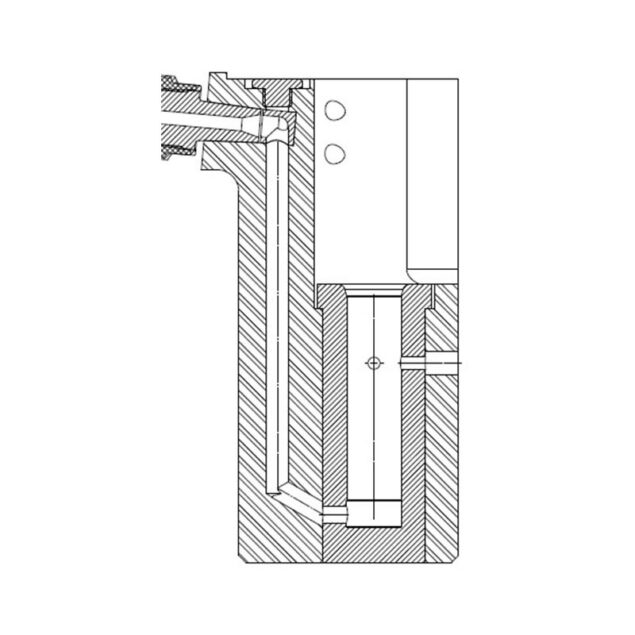

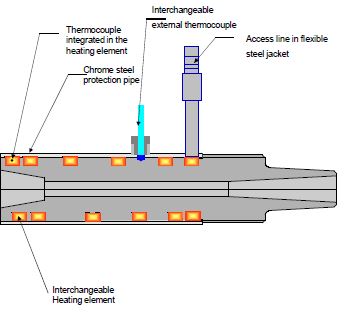

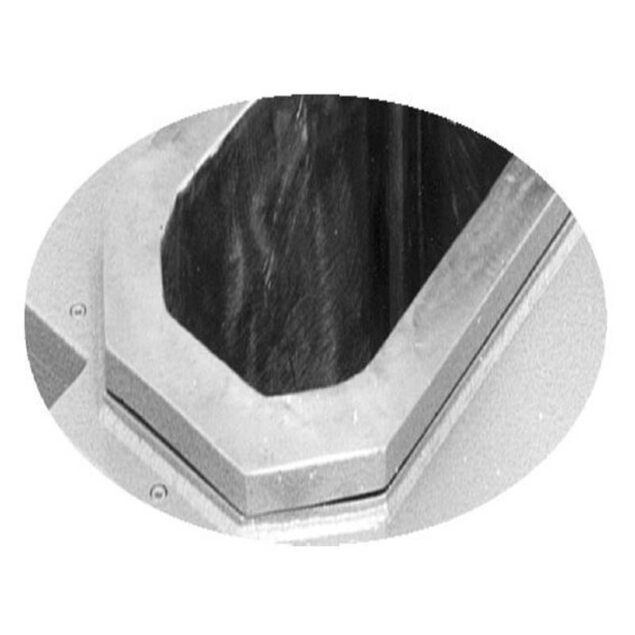

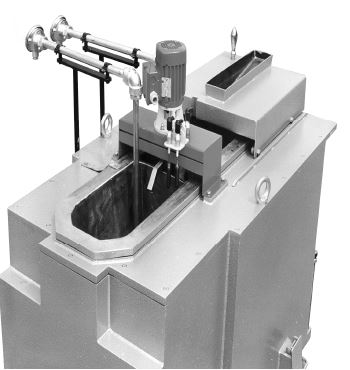

GOOSENECKS

The angular heating cartridges in the gooseneck make it possible, that they can be removed without removing the heated nozzle.

.

GOOSENECK OVERHAUL

The overhaul includes by default:

- cleaning of the gooseneck in acid bath

- the used shot sleeve will be pressed out of the gooseneck

- gooseneck will be reworked

- a new shot sleeve

- new shot-sleeve will be pressed into the gooseneck and honed

to exact dimension for the plunger

If necessary, of course all additional repairs are done after

clearance:

For example:

- drilling out the heating cartridges

- insertion of chrome steel cores for the heating cartridges

- insertion of a new cone sleeve for the nozzle (flow properties)

SHOT SLEEVES

MATERIAL:

- forged hot working steel, material 1.2343/44

- through hardened

- ground to dimension

- honed to dimension

- surface additionally nitrided

- at 2 mm thick to 61 HRC, the rest to 56 HRC

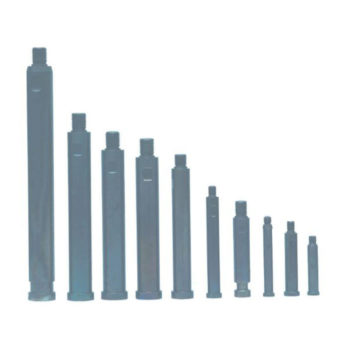

PLUNGERS

- Material: forged hot working steel 1.2344

- Processing: the external surface is ground to dimension

- Surface treatment: through hardened in vacuum

Also available as a set (incl. 3 plunger rings)!

PLUNGER RODS

- Material: reinforced hot working steel 1.2312

- Surface treatment: browned

Of course we can also produce plunger rods according to your drawing.

PLUNGER RINGS

Each plunger ring is individually ground to ensure, it runs at 100% on cycle.

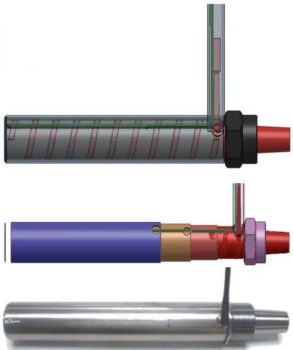

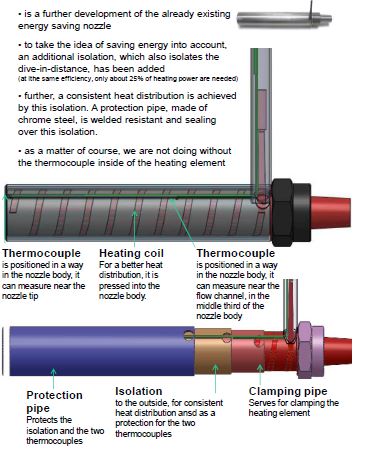

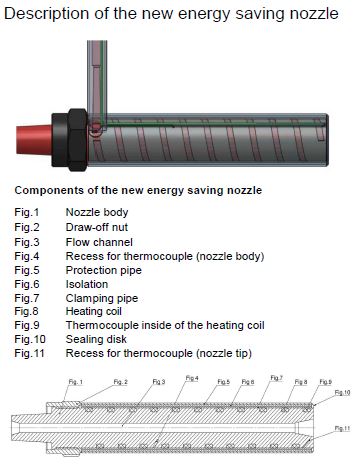

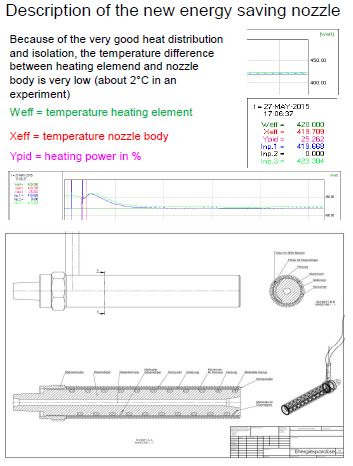

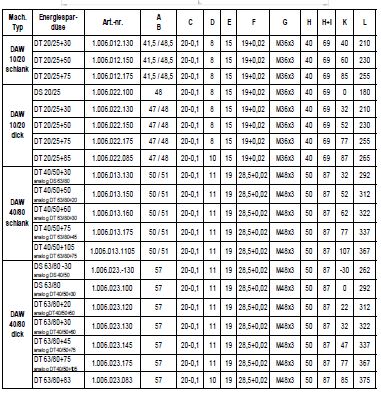

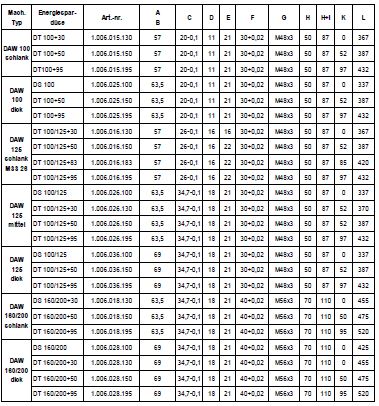

THE NEW GENERATION OF ENERGY SAVING NOZZLES

Eliminate environmental effects and save up to 70% of energy!

ENERGY SAVING NOZZLES

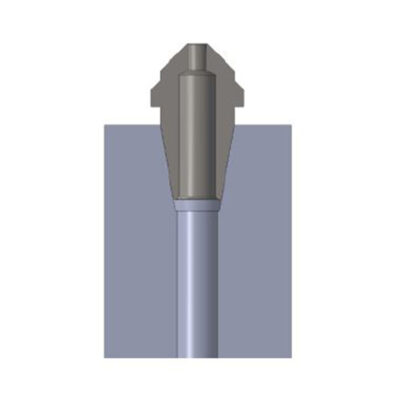

NOZZLE TIPS

- Material: forged hot working steel 1.2344

- Heat treatment: through hardened under vaccum

- Processing: we grind the sealing surface of the cone

- available with or without thread

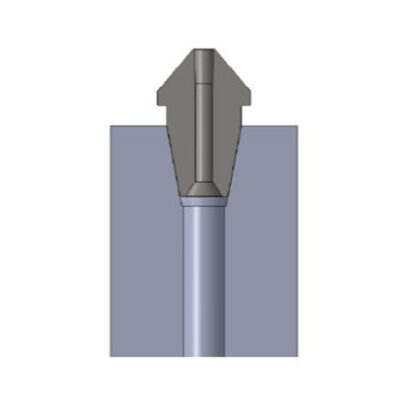

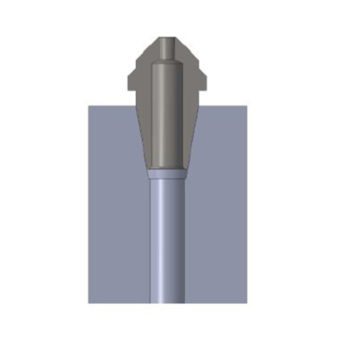

NOZZLE TIPS WITH OFFSET DRILLING

- higher heat capacity due to higher volume

- less flow resistance

- wear-out due to pressure peaks is relocated into the nozzle tip,

- The lifetime of the nozzle body is increased

Disadvantage:

- The freezing point has to be exactly defined

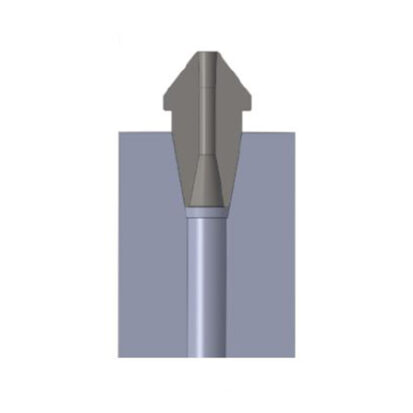

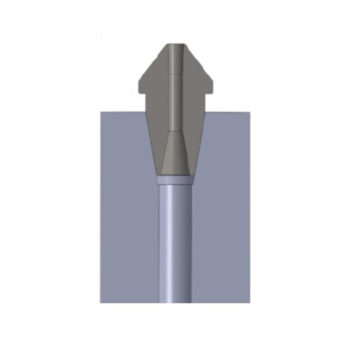

NOZZLE TIPS WITH CONICAL OFFSET DRILLING

- Less pressure peaks due to the smoother transition

Disadvantage:

- Pressure peaks are located in the nozzle body area

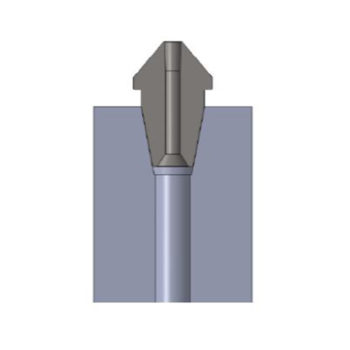

NOZZLE TIPS WITH OFFSET DRILLING

- The position of the freezing point

doesn‘t have to be exactly defined. - Increase of the flow velocity

Disadvantage

- A very high pressure peak is located in the nozzle body area

- high loss of the specific injection pressure

DRAW-OFF NUT FOR NOZZLE TIPS

DRAW-OFF NUT FOR NOZZLE TIPS

CRUCIBLES

Material:

- cast steel edition (cast steel)

- stainless steel edition (stainless steel)

The 2-chamber crucible can only be provided in the stainless steel edition.

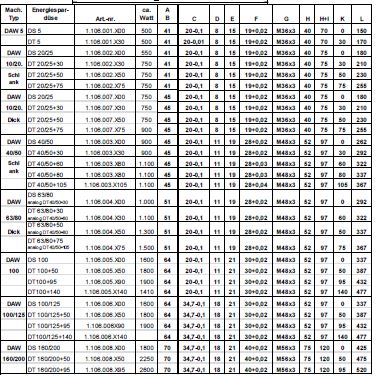

HP HEATING CARTRIDGES

cartridges before installation. The easiest way to dry out the cartridges is to put them into the furnace of the machine or into the tempering furnace with 180° while removing the old cartridges.

Advantages of G-S-D HP heating cartridge

• optimal distribution of power

• knock out plug

• special insulated cable exit

• high resistant heating element

THERMOCOUPLES

- 1/4 “fast-lock“ or ¼ „screw-lock“

- length of the cable 1,5 m

- optional NiCrNi or FeCuNi

Special length of the cable or connection on demand.

ANGULAR THERMOCOUPLES (Temperature sensors)

DIGITAL TEMPERATURE CONTROLLER

Config. 1 = Standard configuration with pre-heating function and thermocouple failure

protection

Config. 2 = pre-heating function, thermocouple failure protection and night reduction

Config. 3 = pre-heating function, thermocouple failure protection and second Thermocouple as overheating – protection

With the frontal PC-Interface an optimal and quick configuration can be created,

imported into the device or exported from the device.

With this interface, a graph, as displayed on the next page, can be recorded.

TWIN-CIRCUIT TEMPERATURE-CONTROLLER

controllers in one steel casing. One only has to put it onto the current net of 220 V of the machine. This controller is especially designed for an uncomplicated change from gas

heated nozzles and goosenecks to electically heated ones.

(An expensive machine installation is not necessary!)

- 01 Goosenecks

- 02 Shot sleeves

- 03 Plungers

- 04 Plunger Rods

- 05 Plunger Rings

- 06 Energy Saving Nozzles

- 07 Nozzle Tips

- 08 Crucibles

- 10 HP Heating Cartridges

- 11 Thermocouples

- 12 Angular Thermocouples

- 13 Digital Temperature Controller

- 14 Twin-Circuit Temperature-Controller

GOOSENECKS

The angular heating cartridges in the gooseneck make it possible, that they can be removed without removing the heated nozzle.

.

GOOSENECK OVERHAUL

The overhaul includes by default:

- cleaning of the gooseneck in acid bath

- the used shot sleeve will be pressed out of the gooseneck

- gooseneck will be reworked

- a new shot sleeve

- new shot-sleeve will be pressed into the gooseneck and honed

to exact dimension for the plunger

If necessary, of course all additional repairs are done after

clearance:

For example:

- drilling out the heating cartridges

- insertion of chrome steel cores for the heating cartridges

- insertion of a new cone sleeve for the nozzle (flow properties)

SHOT SLEEVES

MATERIAL:

- forged hot working steel, material 1.2343/44

- through hardened

- ground to dimension

- honed to dimension

- surface additionally nitrided

- at 2 mm thick to 61 HRC, the rest to 56 HRC

PLUNGERS

- Material: forged hot working steel 1.2344

- Processing: the external surface is ground to dimension

- Surface treatment: through hardened in vacuum

Also available as a set (incl. 3 plunger rings)!

PLUNGER RODS

- Material: reinforced hot working steel 1.2312

- Surface treatment: browned

Of course we can also produce plunger rods according to your drawing.

PLUNGER RINGS

Each plunger ring is individually ground to ensure, it runs at 100% on cycle.

THE NEW GENERATION OF ENERGY SAVING NOZZLES

Eliminate environmental effects and save up to 70% of energy!

ENERGY SAVING NOZZLES

NOZZLE TIPS

- Material: forged hot working steel 1.2344

- Heat treatment: through hardened under vaccum

- Processing: we grind the sealing surface of the cone

- available with or without thread

NOZZLE TIPS WITH OFFSET DRILLING

- higher heat capacity due to higher volume

- less flow resistance

- wear-out due to pressure peaks is relocated into the nozzle tip,

- The lifetime of the nozzle body is increased

Disadvantage:

- The freezing point has to be exactly defined

NOZZLE TIPS WITH CONICAL OFFSET DRILLING

- Less pressure peaks due to the smoother transition

Disadvantage:

- Pressure peaks are located in the nozzle body area

NOZZLE TIPS WITH OFFSET DRILLING

- The position of the freezing point

doesn‘t have to be exactly defined. - Increase of the flow velocity

Disadvantage

- A very high pressure peak is located in the nozzle body area

- high loss of the specific injection pressure

DRAW-OFF NUT FOR NOZZLE TIPS

DRAW-OFF NUT FOR NOZZLE TIPS

CRUCIBLES

Material:

- cast steel edition (cast steel)

- stainless steel edition (stainless steel)

The 2-chamber crucible can only be provided in the stainless steel edition.

HP HEATING CARTRIDGES

cartridges before installation. The easiest way to dry out the cartridges is to put them into the furnace of the machine or into the tempering furnace with 180° while removing the old cartridges.

Advantages of G-S-D HP heating cartridge

• optimal distribution of power

• knock out plug

• special insulated cable exit

• high resistant heating element

THERMOCOUPLES

- 1/4 “fast-lock“ or ¼ „screw-lock“

- length of the cable 1,5 m

- optional NiCrNi or FeCuNi

Special length of the cable or connection on demand.

ANGULAR THERMOCOUPLES (Temperature sensors)

DIGITAL TEMPERATURE CONTROLLER

Config. 1 = Standard configuration with pre-heating function and thermocouple failure

protection

Config. 2 = pre-heating function, thermocouple failure protection and night reduction

Config. 3 = pre-heating function, thermocouple failure protection and second Thermocouple as overheating – protection

With the frontal PC-Interface an optimal and quick configuration can be created,

imported into the device or exported from the device.

With this interface, a graph, as displayed on the next page, can be recorded.

TWIN-CIRCUIT TEMPERATURE-CONTROLLER

controllers in one steel casing. One only has to put it onto the current net of 220 V of the machine. This controller is especially designed for an uncomplicated change from gas

heated nozzles and goosenecks to electically heated ones.

(An expensive machine installation is not necessary!)