PERIPHERALS

In order to meet our own requirements and those of our customers, we are constantly developing our range of peripherals further.

- Die Spraying Units

- Control Scales

- Slat Conveyors

- Screw Separator Units

- Vibration Separator Unit

- Separating Drum

- Die Temperature Control Units

- Zinc Pump

- Warmholding & Melting Furnace

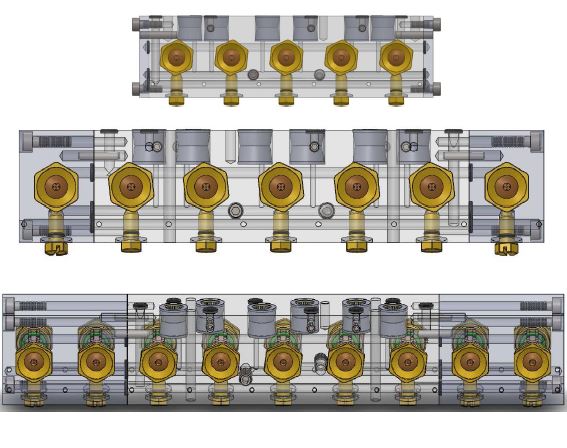

DIE SPRAYING UNITS

Spraying heads:

For our servomotor die spraying units we also supply special spraying heads with integrated valve technology.

CONTROL SCALES

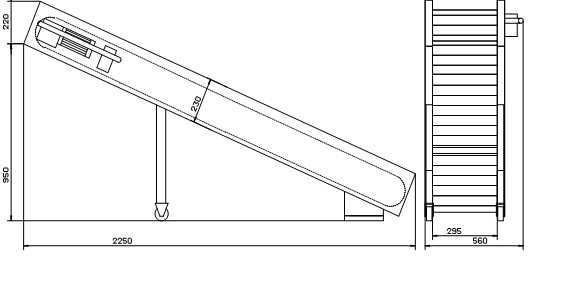

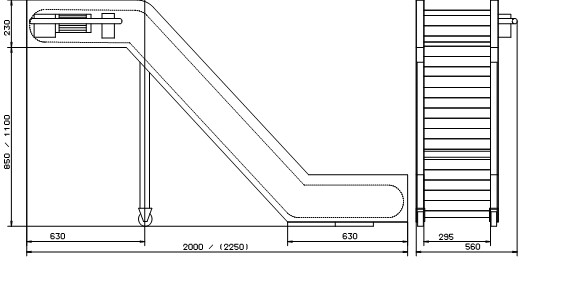

SLAT CONVEYORS

Application:

The G-S-D slat conveyors were designed especially for the transport of hot pressure casting parts.The slat conveyors are offered in two different sizes and constructions. On demand, it is of course possible to offer a slat conveyor according your special requirements in shape and size other than the standard conveyors.

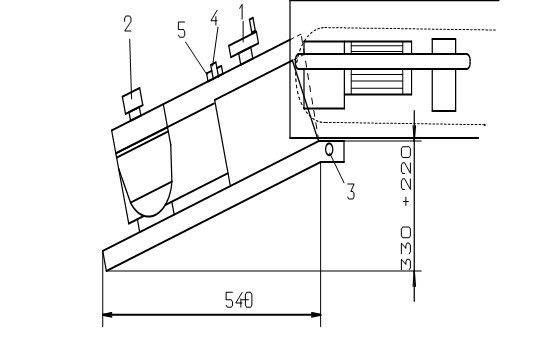

SCREW SEPARATOR UNITS

Technical data:

Direction of ejection = right

- Roller – height adjustment

- Roller angel adjustment screw

- Angel adjustment for total seperator unit

- Speed adjustment for separating roo

- On – Off roler motor

Direction of ejection left Direction of ejection right

VIBRATION SEPARATOR UNIT

SEPARATING DRUM - separating and sorting of spures, castings and over flows

The sizes of the slots are adjusted simply by rotating the two outer covers. This two moving covers are fixed into position with two quick-release locks each.

The outer cover, is divided into two sections. it is therefore possible, to divide the separating drum into two different sorting sections.

Within the front area of the drum, the slots can be adjusted so narrow that only the small over flows can pass through the sifter.

In the next area of the drum, the larger casting are sorted out at the same time trough the wider slots.

The large sprues pass, as usual, through the total lenght of the drum and fall out in to a container.

DIE TEMPERATURE CONTROL UNITS

Used die temperature control units are partly available from stock.

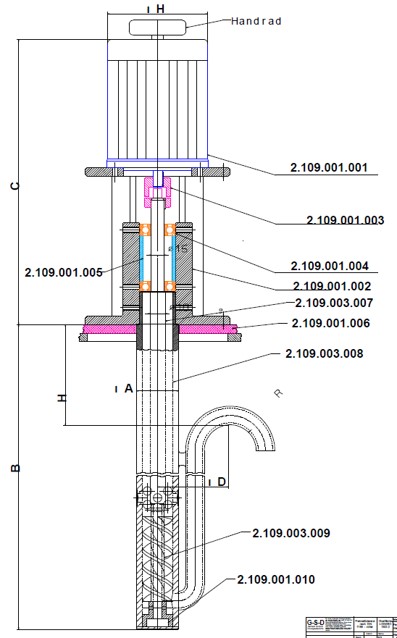

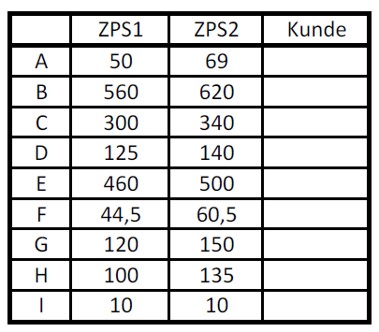

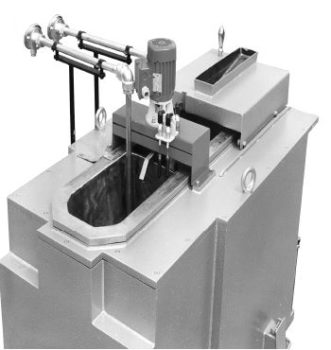

ZINC PUMP

This closed construction also reduces the problem of freezing. The plug-in type electrodes make the installation and dismantling for maintenance more easy.

A special insulation of the pump is very important for the lifetime of the motor.

The dismantling of the pump shaft and screw can be done without removing the pump housing from the metal bath.

Both, the pump screw and the housing are made of hardened steel !

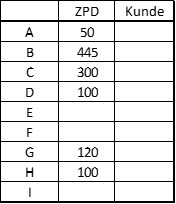

WARMHOLDING AND MELTING FURNACE

As well as new and remodeling of existing furnace

The the newest special thermal insulation guarantees high energy saving. Improved foundry environment and lower heating capacity are the result. Two modern heating register which can be pulled out easily for maintenace without removing the crucible. The standardized measurements allow easy adaption to

- Die Spraying Units

- Control Scales

- Slat Conveyors

- Screw Separator Units

- Vibration Separator Unit

- Separating Drum

- Die Temperature Control Units

- Zinc Pump

- Warmholding & Melting Furnace

DIE SPRAYING UNITS

Spraying heads:

For our servomotor die spraying units we also supply special spraying heads with integrated valve technology.

CONTROL SCALES

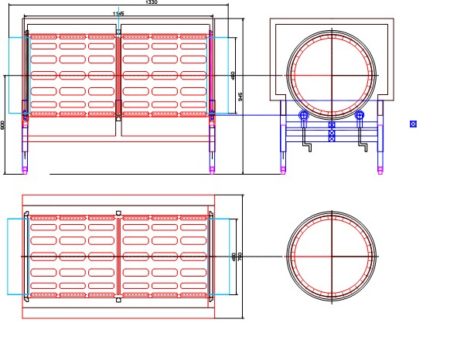

SLAT CONVEYORS

Application:

The G-S-D slat conveyors were designed especially for the transport of hot pressure casting parts.The slat conveyors are offered in two different sizes and constructions. On demand, it is of course possible to offer a slat conveyor according your special requirements in shape and size other than the standard conveyors.

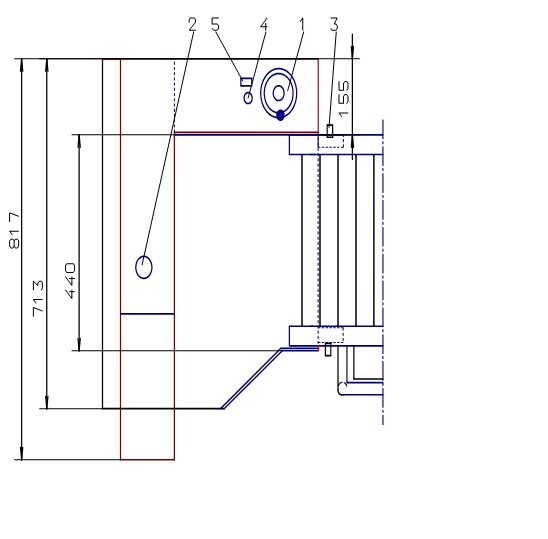

SCREW SEPARATOR UNITS

Technical data:

Direction of ejection = right

- Roller – height adjustment

- Roller angel adjustment screw

- Angel adjustment for total seperator unit

- Speed adjustment for separating roo

- On – Off roler motor

Direction of ejection left Direction of ejection right

VIBRATION SEPARATOR UNIT

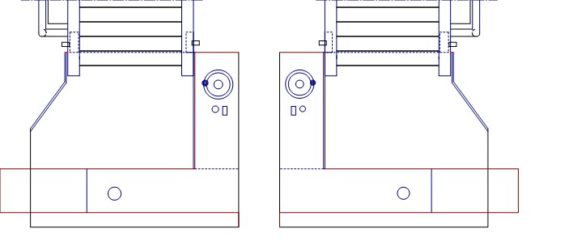

SEPARATING DRUM - separating and sorting of spures, castings and over flows

The sizes of the slots are adjusted simply by rotating the two outer covers. This two moving covers are fixed into position with two quick-release locks each.

The outer cover, is divided into two sections. it is therefore possible, to divide the separating drum into two different sorting sections.

Within the front area of the drum, the slots can be adjusted so narrow that only the small over flows can pass through the sifter.

In the next area of the drum, the larger casting are sorted out at the same time trough the wider slots.

The large sprues pass, as usual, through the total lenght of the drum and fall out in to a container.

DIE TEMPERATURE CONTROL UNITS

Used die temperature control units are partly available from stock.

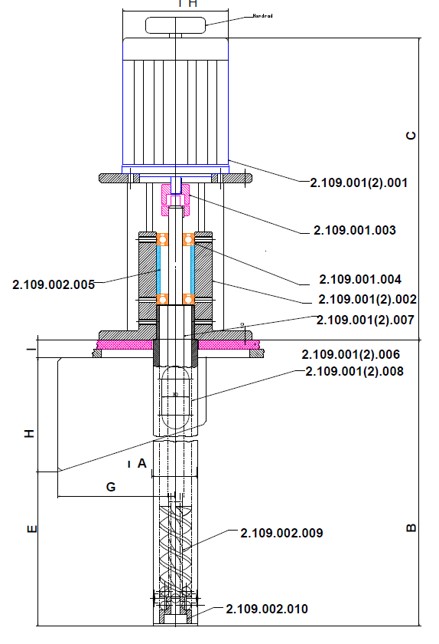

ZINC PUMP

This closed construction also reduces the problem of freezing. The plug-in type electrodes make the installation and dismantling for maintenance more easy.

A special insulation of the pump is very important for the lifetime of the motor.

The dismantling of the pump shaft and screw can be done without removing the pump housing from the metal bath.

Both, the pump screw and the housing are made of hardened steel !

WARMHOLDING AND MELTING FURNACE

As well as new and remodeling of existing furnace

The the newest special thermal insulation guarantees high energy saving. Improved foundry environment and lower heating capacity are the result. Two modern heating register which can be pulled out easily for maintenace without removing the crucible. The standardized measurements allow easy adaption to